At a time when airlines are demanding ever more hours and performance from their engines, built-in reliability and best-in-class engineering is vital to ensure the aircraft they power are in the air as much as possible and delivering on their efficiency promises.

However, so too are the support networks the engine manufacturers provide their customers, ensuring that when an engine does require maintenance, repair or overhaul (MRO), the time it spends off wing is kept to a minimum.

For more than four decades, GE Aerospace’s engine MRO facilities across Asia-Pacific have been at the cutting edge of innovation – and the drive to do things better, and quicker, is not letting up.

In fact, just last year, GE Aerospace announced plans to invest $75 million in its MRO facilities in the region, building on an earlier $45M commitment as part of a wider $1 billion global MRO spending plan announced in 2024.

The company’s relentless investment in everything from automation and innovative repair processes to re-thinking shop-floor layouts to spur efficiency has been with one aim in mind.

“It’s simple: when an engine is off the wing it’s not been utilized,” explains Iain Rodger, managing director at GE Aerospace Component Repair Singapore, the company’s flagship facility in the region. “Our job is to shorten turnaround times and get the engine back to the customer as fast as possible.”

The business – which operates across three locations – repairs parts for all GE Aerospace and CFM International commercial jet engines, including turbine blades and nozzles, high-pressure compressor (HPC) blades and vanes, and combustors. It is responsible for more than 60% of the company’s global repair volume.

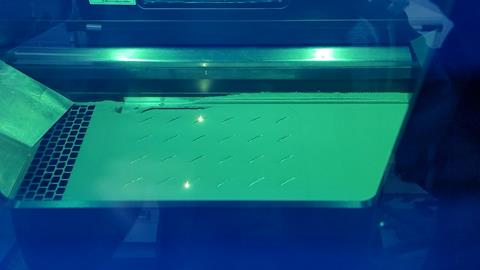

GE Aerospace Component Repair Singapore has been a pacesetter in technologies such as additive manufacturing (AM). While AM – sometimes known as 3D printing – has been making a difference in aerospace manufacturing for more than a decade, its use in the aftermarket is still relatively new.

The site has been using AM for HPC blade tip repairs since 2021, on the CF6 and CFM56and will go “straight to additive” on the GEnx and LEAP. Meanwhile, the “next big step” could be using AM for so-called “hot end” parts, says Rodger.

“We are proud to have been the first MRO facility worldwide to pioneer additive technology in repairing jet engine components,” he says. Again, the incentive is not just winning the innovation race: there is a direct and immediate payback for the customer.

“Applying this technology in the engine repair process doubles the number of parts we can repair daily, shortening turnaround times and allowing customers to return their aircraft to the skies more quickly”, he says. “Additive processes are 60% faster, need 50% less post-processing. And have a 40% smaller footprint.”

Another technology of which the Singapore site has been at the forefront is automated laser weld repairs on high-pressure and low-pressure turbine blades. Installing advanced laser welding machines has led to the replacement of 54 manual welding booths with just 13 automated stations, with welders “upskilled” to other roles within the business.

Many such bold efficiency moves have been spurred by the introduction of FLIGHT DECK, GE Aerospace’s proprietary lean operating model.

FLIGHT DECK is all about “changing behaviours” and encouraging management and staff to think about continuous improvements to workflows and production cultures, says Rodger.

“It means understanding our processes with a view to introducing flow and using automation where it will make a difference to flow and identifying where the technology can take us, whether it’s additive repairs, robotic finishing or laser welding,” he adds.

According to Rodger, following those FLIGHT DECK fundamentals has led to the Singapore facility reducing its turnaround times (TAT) on components by as much as half.

“On high-pressure turbine nozzles, our largest business, we reduced TAT by 30%, improved productivity by 8%, and increased output by 35%, just by re-laying out the equipment from three floors of production to two,” he says.

The aim, he maintains, is to detect and address bottlenecks in the production process. Again, the familiar percentage targets: “With any of this we are aiming to be 60% faster, to have 50% less processing, and 40% less footprint,” says Rodger.

Rodger insists that all GE Aerospace’s investments in its service capabilities are about “doing more with less” with the customer benefiting from quicker turnarounds and more durable parts.

“The more repairs we can do, the more product we can get back into the market,” he says. “And if we can keep these parts in service for longer, the operator ultimately benefits from more time on wing.”

The investment in the region’s services footprint has also seen GE Aerospace’s overhaul operation in Malaysia expand. The investment will support expansion plans for MRO work on CFM56 and CFM LEAP engines, doubling the LEAP engine MRO shop visit capacity within the next three years.

A state-of-the-art engine test facility, using the latest software and hardware and dedicated to LEAP 1A and 1B engines, will also be introduced. Additional equipment will be installed to meet rising demand, alongside training programs for new employees and upskilling initiatives for existing teams.

The expansion is expected to create new employment opportunities, with 20% year-on-year growth in high-skilled job openings anticipated over the next three years.

Across the region, the GE Aerospace teams are expanding to support the industry ramp-up, with FLIGHT DECK providing a consistent framework to strengthen operational performance and deliver added value for customers.