In a famous quote from the timeless 1967 movie “The Graduate,” a young Dustin Hoffman receives some prescient advice. His father’s friend tells him about the path to future success: “One word…plastics.” Few would have believed then that even airplanes would one day be built out of plastics.

Today, thanks to advances in thermoplastic manufacturing, more and more aircraft components are being created out of advanced composite materials – a form of plastics. These composites are helping make the aviation industry more sustainable, and they can be manufactured via a more streamlined and sustainable process. Collins Aerospace is helping shape the future of thermoplastics by pairing its long history of aerostructures manufacturing with newly expanded capabilities augmented by its 2021 acquisition of another leader in the field, Dutch Thermoplastic Components BV (DTC).

“Collins was already an industry leader with its specialized capabilities in advanced composites, and for DTC to join that team creates expanded capabilities and the opportunity to bring even more innovations to the marketplace,” said David Manten, founder of DTC and current General Manager of Engineered Thermoplastics for Advanced Structures at Collins Aerospace. “Not only does Collins have the proven manufacturing expertise required to offer next-generation products, but we also have a loyal and established customer base that we will continue to support and grow.”

Bringing the benefits of thermoplastics to the aerospace industry

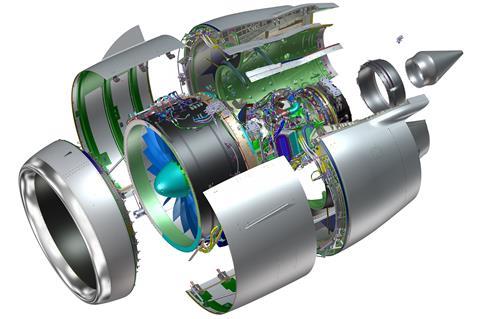

In an effort to create compelling, more sustainable solutions for its global customers, Collins is continuously seeking advancements in nacelle systems, fan cowls, thrust reversers and other highly engineered aerospace structural components that are lighter, more efficient and produced at rapid rates to enable more sustainable flight.

“By shifting to large thermoplastic composite manufacturing, we can leap forward in all these areas by replacing energy- and labor-intensive assemblies of thermoset composite and metallic structures with more automated, out-of-autoclave, weldable structures that result in less energy consumption, reduced weight and cost, and higher production rates,” explained Manten. “And as an added advantage, thermoplastics are recyclable and more environmentally friendly.”

These new materials, and their methods of manufacture, have the potential to:

- Reduce manufacturing cycle time by 80 percent;

- Decrease the weight of structures by as much as 50 percent compared to earlier iterations; and

- Incorporate sustainability improvements resulting in fewer emissions, a fully recyclable product and lower landfill output.

Shaping a more sustainable future

When you narrow it down, thermoplastic composite technology plays an important role in energy efficiency. With traditional aircraft components made of bonded metallics and thermosets (, the manufacturing process requires products to be cured in large autoclave ovens that consume large amounts of energy to get the necessary amount of heat and pressure.

In contrast, thermoplastic composites don’t require the same chemical reactions so they can be manufactured via more efficient, out-of-autoclave processes that greatly reduce energy usage. With thermoplastics, manufacturing processes can be reduced from hours to minutes while the material is shaped into its desired geometry. In addition, thermoplastic composites can be incredibly robust and more resistant to impact and high temperatures.

While thermoplastics manufacturing is quicker and more efficient, it also provides sustainability benefits because the resulting components are re-moldable and therefore recyclable – making them more attractive than metallic and thermoset parts. As fuel efficiency grows in importance for mission performance, aerospace customers are counting on manufacturers for lighter-weight products that address specific fuel-consumption metrics. Thermoplastics can reduce the weight of structural components by up to 50 percent as compared to metallic solutions.

“We’re developing key technologies for our customers that not only provide the results that matter to them, but also have the potential to transform the way we do business,” Manten said. “By enabling their visions, we can better ensure we reach our own.”

New acquisition expands Collins’ capabilities

For more than 20 years, DTC developed and manufactured thermoplastic-composite aerospace parts used as structurally loaded components in applications including fuselages, doors, wings and flight control surfaces. A pioneer in this field, DTC has evolved into an industry leader.

As a supplier of thermoplastic composite parts to 20 different aircraft types, DTC developed strong customer relationships while being highly engaged in the development of new material and process specifications. Key to its success was the company’s ability to invest in new advanced processing technologies that were embraced by its customers.

Now that DTC has become part of Collins Aerospace, Collins will leverage this unique expertise as part of a broader initiative to bring develop a new level of advanced, in-house thermoplastics capabilities and a distinctive product portfolio for the benefit of current and future customers.

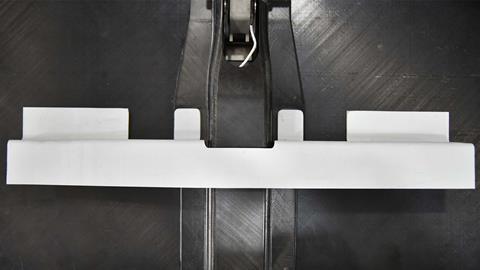

The thermoplastic technologies in this new toolbox include automated fiber placement and multiple advanced welding technologies that allow Collins to build larger, more complex and integrated aerostructures compared to the components currently fabricated by the former DTC (and current Collins) team in the Netherlands.

“Right now, we’re on track to demonstrate a thermoplastic fan cowl by welding a large, curved frame to a fiber-placed skin in 2022,” added Manten.

Providing innovative aerostructures for 80 years

Advancing manufacturing is not new for Collins Aerospace. Since the 1940s, Collins has pioneered the use of cutting-edge process and material technologies to create nacelle systems and engineered structures for commercial and military aircraft. Long recognized as a leader in advanced metals and composites, the company has continually expanded, explored and incorporated modern material and process applications into its products. Today, Collins is actively engaged in the research and development of modern materials that are redefining the industry, such as composites, ceramics and titanium.

By virtue of its acquisition of DTC, Collins has operated in the epicenter of thermoplastic composite technology for more than 20 years while remaining committed to future development. With two advanced thermoplastic manufacturing sites in the Netherlands and California, Collins is bringing process efficiency along with lightweight, durable and sustainable products to the global aerospace industry.