Aviation battery start-up H55 – a spin-out from the Solar Impulse project – is hailing a major milestone, having successfully proved to the European regulator that its Adagio battery modules are certifiable.

This follows a six-month test campaign, completed on 19 December, supervised by the European Union Aviation Safety Agency.

“For us it’s a fantastic moment – nobody else has reached this level,” says executive chairman and co-founder Andre Borschberg.

Critically, the evaluations used production battery modules built by H55 at its Sion, Switzerland facility rather than prototype hardware.

H55 built more than 100 test articles for the campaign, which covered environmental, safety, functional, and performance conditions under worst-case failure modes – including thermal runaway tests without propagation.

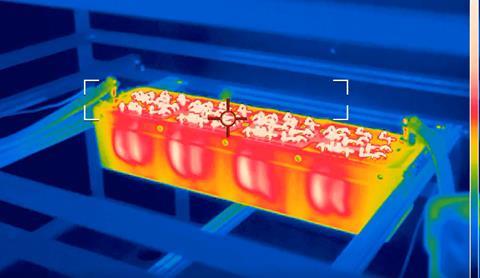

Rather than attempting to contain a thermal runaway by shielding – typically housing the cells in a fireproof titanium box – H55 opts for a different approach, preventing fire propagation at cell level.

This is achieved by “encapsulating” the cells so that energy is released in a specific direction away from other cells “so that we can guide it out of the module in a controlled way”, he says. “It allows us to avoid any propagation of the fire to adjoining cells,” he says.

While not an approval in its own right – batteries are certificated as part of the propulsion system or the aircraft itself – the work nonetheless provides airframers with a crucial regulatory building block.

“In either case, they ask for the battery to pass these tests. By having done those already we can provide the aircraft manufacturer with the pile of documents proving that.

“This will help accelerate the development and commercialisation of electric aircraft.”

Borschberg says H55 is achieving a “pretty good” energy density of around 200Wh/kg at module level.

“Of course, you will see people offering 300[Wh/kg] but you have a technology which you can’t certify because you can’t achieve the fire containment, or you cannot have stable production because it’s a special lab production technology,” he adds.

H55’s Sion battery fabrication plant, sized to build 100 battery packs per year, is now ready to ramp-up; Borschberg expects the first battery modules to enter service in early 2027 aboard the Czech-built Bristell B23 Energic trainer.

Alongside the Sion plant, H55 has another production facility in Montreal in Canada. That site is supporting its work with RTX companies Pratt & Whitney Canada and Collins Aerospace to demonstrate a hybrid-electric powertrain aboard a De Havilland Canada Dash 8-100 turboprop.

Originally due to fly in 2024, Borschberg says the modified twin-turboprop will take to the skies later this year or in early 2027.