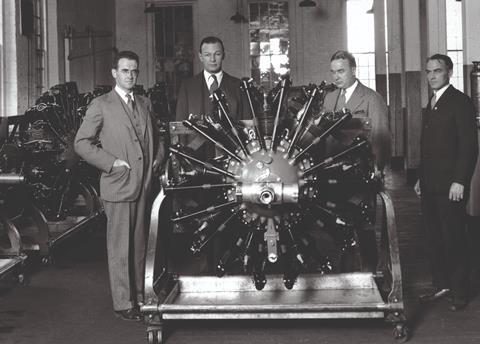

Shane Eddy is at the helm of a legendary aviation brand born 100 years ago. That was when a former US Army lieutenant, Frederick Rentschler, embarked on his mission to turn Pratt & Whitney – the name of a machine tool firm in Connecticut that provided his initial financial backing – into a powerhouse in the young and fragmented world of aviation propulsion.

While the market Pratt & Whitney began serving in 1925 was very different to today – and a century of technological advancement has seen its early Wasp piston engines for the US Navy evolve into the likes of the Pratt & Whitney GTF* engine, PW800, and F135 – the ethos behind the business Rentschler established in a Hartford former tobacco warehouse has not changed.

All employees of the company – and the tens of thousands who came before – are fellow guardians of a formidable reputation, according to Eddy, an aerospace veteran who became Pratt & Whitney president in March 2022. “Since our founding, the people of Pratt & Whitney have prided themselves on building the safest, most dependable engines. Everything we do is about connecting people, growing economies, and defending freedom,” he says.

“There are 45,000 people working here every day to uphold that legacy. That promise of dependable engines is literally stamped on every engine we produce. It is a promise that our entire team lives by, and one that means our customers continue to place their trust in us.”

Pratt & Whitney’s achievements over those 100 years have been impressive. After establishing itself in the post-Great War military market with the R-1340 Wasp, it provided the propulsion for one of the most successful passenger transports of the 1930s, the Douglas DC-3.

During World War II, production of Wasp engines ramped up to the hundreds of thousands, providing more than half the total horsepower for Allied aircraft, and serving as a major contributor to the Allies’ victory in the air.

Later, its JT3D helped usher in the jet age with the Boeing 707, while in the 1960s and 1970s the Pratt & Whitney JT8D and JT9D families powered a generation of mass-produced airliners, including the Boeing 727 and 747, the McDonnell Douglas DC-9 and DC-10, and the Airbus A300/A310. The company continued to advance its technology in the 1980’s and 1990’s with the PW2000 engine for the Boeing 757 and the PW4000 engine family which powers the 747, 767, 777, MD-11, A300/A310 and A330 aircraft.

Toward the end of the century, the V2500* from the Pratt & Whitney-led International Aero Engines consortium became the company’s big contender in the fast-growing narrowbody segment. It continues to fly on some 2,800 Airbus A320ceo family aircraft, for over 150 operators. More than 7,900 engines have been built, and it is still manufactured as a line fit for the Embraer C-390 military transport.

On the defence side, for the past 40 years Pratt & Whitney products – from the F100 on the Boeing F-15 and the Lockheed Martin F-16 to the F135 on Lockheed’s F-35 – have “defined modern fighter propulsion,” remarks Eddy.

Future focused

However, while Eddy can justifiably reflect on the company’s storied history, his focus is very much on Pratt & Whitney’s future. In the defence market, the F100 and F135 continue to be crucial to its strategy, with continued production of the F135 secured with its Engine Core Upgrade as well as new export orders, upgrades, and platform applications giving new life to the F100. Pratt & Whitney is also the propulsion provider for the US Air Force’s sixth generation bomber, the B-21.

For Pratt & Whitney Canada, the PT6* series “is still going strong after more than 60 years of service”, powering a wide variety of fixed wing and helicopter applications, and with a pipeline of continuous innovation. The PW800 – which powers some of the latest jets from Gulfstream and Dassault – is the most recent arrival in the business aviation segment, joining the in-production PW300 on the Cessna Citation Latitude and Dassault Falcon 8X, the Embraer Phenom 100’s PW600, and the PW500 that powers its larger sister the Phenom 300.

But the fastest growing part of Pratt & Whitney’s business is its GTF engine. Launched on the then-Mitsubishi Regional Jet in 2008, variants went on to secure exclusive positions on two more small-narrowbody programmes, the Bombardier CSeries (now the Airbus A220) and Embraer E2.

Most importantly, in terms of market potential, the PW1100G-JM variant of the GTF was chosen as one of two engine options for the Airbus A320neo family, the European manufacturer’s successor to the original A320.

Eddy’s tenure at Pratt & Whitney – before landing the top job, he served as senior vice-president and chief operations officer responsible for safety, quality, delivery, and cost for six years from 2016 – has coincided with what has been the most exciting period for the GTF programme, but not one that has been without challenges.

When he moved to East Hartford, the company had just begun delivering the first GTFs to Airbus and Bombardier. At the same time, shipments of the F135 – the first production example of which had left the factory in 2009 – were ramping up fast in line with deliveries of the F-35 to the US Air Force, Marine Corps and Navy, as well as allies.

“With the GTF, the F135 and others, we had the winning products,” Eddy recalls. “The challenge was industrially ramping up. But by the final quarter of 2019, I could say we had reached the intended production rate of these products, so a lot was accomplished in that three-year span.”

However, as Pratt & Whitney and the wider sector confidently entered the new decade, order books brimming and passenger numbers at record highs, reports emerged of a highly infectious and potentially life-threatening coronavirus spreading to all continents from China. Within weeks, most commercial aviation was grounded and would stay that way for more than 15 months, with the aftershocks in terms of disruptions to the supply chain remaining until this day.

Eddy describes Covid-19 and its long-lasting effects as “maybe the most difficult time that I’ve seen in our industry”. However, he says the pandemic is just one of many challenges the business has successfully steered through during its eventful history – from surplus aircraft and engines flooding the market after World War II to the decline in military budgets in the 1990s following the fall of the Soviet Union.

“I’m really proud of the fact that we navigated it with very few compulsory departures and could by July of that year be in a position where we were hiring,” he says. Voluntary retirements meant the loss of some experienced staff and created “generational talent change” at the company. “We’ve hired roughly 25,000 people post-pandemic, which presents an incredible opportunity to continue evolving our culture,” notes Eddy.

Another major event during this time was the April 2020 merger of Pratt & Whitney then-parent United Technologies (UTC) with Raytheon to create Raytheon Technologies. The coming together came shortly after UTC’s absorption of Collins Aerospace (formerly Rockwell Collins) and created a grouping of three powerful aerospace and defence brands – avionics, electrics, and aerostructures specialist Collins; missiles and defence technologies house Raytheon; and Pratt & Whitney. Then in 2023, Raytheon Technologies rebranded as RTX, as it is known today.

“We are now part of the world’s most advanced aerospace and defence systems provider,” says Eddy. “The creation of RTX has brought together an unmatched suite of talent and capability, with almost 60,000 engineers across the three businesses at its heart.”

While UTC was more of an industrial holding company (Pratt & Whitney’s former sister companies Otis and Carrier made escalators and air conditioning systems), RTX is an entity dedicated to commercial aviation and defence. “It means we can really leverage operating synergies and harmonize processes to drive performance,” says Eddy.

One example is RTX Lifecycle Program Management (RLPM). Drawing upon best practices from the three businesses, RLPM provides a common framework for how programmes are managed from cradle to grave. “This allows us to push for continuous improvement as a team of 180,000 people,” he says. “It means we can have a very intense customer focus.”

So what is Pratt & Whitney’s place in the market today? With more than 17,000 customers around the world and a 90,000 engine-strong installed base, it remains in a “leadership position” in the segments it serves, according to Eddy.

In defence, “we are the only fifth generation engine provider at scale”. The company has delivered more than 1,300 F135 engines – with the engine recently passing a million flight hours – and was awarded a contract for the Engine Core Upgrade last year. In addition, it supports more than 180 Lockheed Martin F-22 Raptors powered by the F119, as well as engines on mobility and long-range strike platforms – in total more than 7,500 in-service military engines.

Pratt & Whitney Canada is the world’s “premier small engine franchise” with an installed base of almost 70,000 engines, from the PT6 on an array of turboprop aircraft, through helicopters to the PW800 at the “premier end of business aviation”, as well as a range of auxiliary power units. Of all the Pratt & Whitney businesses, it is the most prolific, having released approximately 25 new engines or variants in the past 10 years. It also takes the lead on many hybrid-electric propulsion development projects, in collaboration with Collins.

Geared for growth

Finally, commercial aviation is the largest and fastest expanding area, with more than 2,300 GTF-powered aircraft with some 80 operators, and an 11,000-strong order book. “The GTF is our biggest growth driver,” says Eddy. “It delivers unmatched performance with better fuel efficiency than its competitor.”

That rapid ramp-up, of course, has come with the sort of challenges that many new programmes that make use of disruptive, advanced technology encounter. A widespread engine recall coupled with a maintenance network that has been racing to keep up with the growing fleet has led to many operators having to ground aircraft for longer than they would have liked.

According to Eddy, the situation is improving as more capacity comes online and process improvements reduce turnaround times. “Largely, we’ve cleared those issues and we’re upgrading the fleet as they come in for a shop visit to improve time on wing,” he says. “We are working hard to lift the fleet for our customers.”

Like every aerospace company, Pratt & Whitney has also had challenges with its supply chain, with many smaller companies still suffering from a loss of experienced staff during the pandemic coupled with a sharp rise in the costs of many raw materials.

From an industrial perspective, Eddy insists Pratt & Whitney has “done a better job on average than our peers” in managing a fragile supply base and says the fact that GTF production output last year was more than 40% higher than it was in 2019 is evidence of this. “Others are not yet back to pre-Covid levels,” he notes.

“Every day we focus on the supply chain,” says Eddy. “We’ve had to work harder with our suppliers. At the end of the day, we rely on each other, so it’s a continuous focus for us. I am not going to sit here and say we are giving customers everything we need to, but every day we are making progress.”

Looking to the future, Pratt & Whitney achieved a major milestone in February when it was granted Federal Aviation Administration certification for its GTF Advantage engine, the latest variant of the PW1100G-JM. The engine is designed to deliver greater take-off thrust, better fuel efficiency and is a more durable configuration – with increased airflow in the core to lower operating temperatures and a state-of-the-art hot section to increase time on wing for customers. The business is also working to make a majority of these improvements to the hot section available as an upgrade for in-service engines.

Deliveries of the new variant are due to begin later this year, and Eddy says the move widens the performance gap with its rival engine, the CFM Leap. “We’ve invested significantly in the Advantage programme,” says Eddy. “We’re the only OEM in the industry making this level of investment in the product.”

He says the Advantage as well as the F135 Engine Core Upgrade and the latest Pratt & Whitney Canada PW127XT that powers ATR and Deutsche Aircraft regional turboprops are just the most recent examples of a determination by the business to “continue to push the boundaries of propulsion”.

Strategic investment

Pratt & Whitney has also been investing heavily in its operations footprint to meet the growing demand, notes Eddy. In 2022, it opened a 111,000 sq m (1.2 million sq ft) state-of-the-art turbine airfoil production facility in Asheville, North Carolina, supporting the GTF, F135, and other engines. Pratt & Whitney recently announced an additional $285 million investment at the facility for an advanced casting foundry, bringing its total investment to nearly $1 billion.

Last year, the business also opened a 79,000 sq m (845,000 sq ft) military engines sustainment centre next to Tinker Air Force Base in Oklahoma City. The $255 million investment will enable Pratt & Whitney to serve domestic and overseas operators of its F135, F117, TF33, F100, and F119 engines.

And in 2023, Pratt & Whitney unveiled its R&D centre in Bengaluru, India’s technology hub, where Collins also has a presence. Cooperation with its sister company on major development projects is crucial to Pratt & Whitney’s strategy, Eddy stresses again.

This is all in addition to continued investment at its mainstay US facilities in Maine, Georgia, Florida, and its home state of Connecticut, where the company maintains its headquarters along with almost 11,000 employees and its main production lines for F135 and GTF engines.

“We are leveraging the capabilities and scale of RTX as we look to the next generation of products – sixth-generation fighter, the next-generation turboprop and the next-generation single-aisle. Hybrid-electric propulsion will be a huge focus of this, and our ability to collaborate with Collins in this space is incredible,” he says.

As he reflects on the centenary and the potential of the next 100 years, Eddy is determined that Pratt & Whitney’s legacy of dependability, safety, innovation, and a relentless push for perfection will continue. “We pride ourselves on having the people who can solve our customers’ greatest challenges,” he says. “We are standing on the shoulders of the generations of employees that came before us, and we have a responsibility to uphold this legacy and pass it along to the next generation.”

*Pratt & Whitney GTF and V2500 are trademarks of RTX Corporation and PT6 is a trademark of Pratt & Whitney Canada Corp.

Committed to Connecticut

For 100 years, Connecticut has been home for Pratt & Whitney. With more than $1 billion invested in the state over the past decade – including more than $550 million in the last five years alone – the Constitution State remains the company’s centre of gravity for its commercial and military programmes.

Today, its East Hartford and Middletown sites serve as flagship locations for high-complexity manufacturing, cutting-edge R&D and major operations across multiple product lines. Notable investments include the new Engineering & Technology Center building in East Hartford (pictured) that opened in 2017 and upgraded infrastructure across both campuses to support future growth.

Some of Pratt & Whitney’s most advanced capabilities are in Connecticut, including the GTF PW1100G and F135 assembly lines supporting engine deliveries for A320neo and F-35 aircraft; F135 titanium integrally bladed rotor – or IBR – manufacturing; repair of GTF and F135 parts and components; advanced coating operations; and many more. Pratt & Whitney will also be bringing PW1900 GTF engine assembly and PW800 testing to Connecticut in the coming years.

Looking ahead, Connecticut will also lead GTF Advantage engine production, the latest variant of the geared turbofan powering the A320neo. With final assembly in Middletown and major components produced in both Middletown and East Hartford, the GTF Advantage cements Connecticut’s position at the centre of modern aerospace manufacturing continuing a legacy of propulsion innovation that spans a century.

Pratt & Whitney at 100

To mark the centenary of Pratt & Whitney, FlightGlobal has partnered with RTX to produce a souvenir special looking at the legacy and future of one of the industry’s most powerful and influential brands.

- 1

- 2

Currently

reading

Currently

reading

Pratt & Whitney at 100: Dependable engines – view from the helm

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13