Since opening its first design office in the tiny New Jersey garage of Pratt & Whitney founder Frederick Rentschler’s associate Andy Willgoos, Pratt & Whitney has never veered from its quest to stay at the leading edge of aircraft propulsion technology – from incremental performance hikes to generational step-changes in fuel efficiency.

That relentless investment in the future continues today. The 2020 merger that brought together Collins Aerospace, Pratt & Whitney and Raytheon established RTX as one of the world’s biggest aerospace and defence companies. With an annual R&D budget of $7.5 billion and more than 60,000 patents to its name, RTX is worth substantially more than the sum of its parts when it comes to technology, with clear collaborative opportunities across its three businesses.

“It’s all about reimagining what we do today, looking for ways to make aviation better for tomorrow and enabling air superiority for the USA and its allies,” says RTX chief scientist Dr Michael Winter. The Pratt & Whitney veteran now helps coordinate research and development projects carried out by RTX’s 57,000 engineers – a third of its total workforce – to ensure alignment with key technology roadmaps across its three businesses.

There are rich opportunities for cross-collaboration. This includes leveraging Collins Aerospace’s leadership in aircraft electrification, which could enable more powerful hybrid-electric propulsion systems, as well as Raytheon’s expertise in integrated air and missile defence systems, which encompasses advanced high-temperature materials.

“There are so many synergies across our company and we incentivise collaboration among our teams,” says Winter, a self-described “lab rat” with a PhD in applied physics. Having spent much of his 37-year career thinking about how to build better engines, he must now ponder the potential of the entire RTX portfolio. Key to that is an integrated cross-company strategy that covers a range of technologies including additive manufacturing, material science, hybrid-electrics, alternative fuels, and artificial intelligence .

Perhaps the clearest overlap in opportunity is in electrification, a discipline that Collins has made its own since the immediate post-war period when predecessor company Sundstrand was designing generators. Since then, the business has pioneered the design of advanced electrical systems on platforms ranging from the Lockheed Martin F-35 to the Airbus A350 and Boeing 787.

Electric solutions

The latest focus is on hybrid-electric propulsion, and how Collins’ electric power technologies can enhance fuel-burning engines. “Before the merger, we worked with Pratt & Whitney and other engine manufacturers as a supplier of accessories,” says Todd Spierling, principal technology fellow at Collins and a specialist in electric power systems. “Now, we think in terms of being an integral part of the actual propulsion system.”

The two businesses’ collaboration was catalysed by the 2021 launch of the RTX Hybrid-Electric Flight Demonstrator, whose propulsion system combines a highly efficiency Pratt & Whitney Canada thermal engine with a powerful 1-megawatt electric motor developed by Collins. “The flight demonstrator really enabled us to get to grips with the challenges of this technology, especially in terms of aircraft integration, but also understand the opportunities,” notes Spierling. “It’s helped us advance a whole range of demonstrator programmes addressing different aircraft applications.”

Another demonstrator is SWITCH, part of the European Union’s Clean Aviation programme, and also involving the likes of MTU Aero Engines, GKN Aerospace and Airbus. Here, the companies are creating a hybrid-electric GTF engine demonstrator, incorporating two of Collins’ megawatt-class electric motor generators due to begin testing next year.

As Spierling explains it, the project will help engineers decide how to target electricity to boost the performance of a conventional engine, whether it is to carry out rapid acceleration or to save fuel during idle conditions. “We are figuring out the best way to use electricity to make a gas turbine more fuel efficient,” he says. “That might involve the engines only using electricity for a few minutes in an hour-long mission, but the additional electrical capability also opens the door to optimising a whole host of systems across the aircraft.”

Alternative fuels

Another route on RTX’s technology roadmap is alternative fuel, including synthetic fuels, sourced from a variety of biomass, waste, or other feedstocks, which many airlines have committed to purchasing in ever greater quantities in the coming years. “We’ve demonstrated that all our modern production commercial engines will be ready to operate with future specifications for 100% synthetic fuels,” says Winter. “The challenge comes from ensuring compatibility across all the other subsystems on the aircraft, as well as for legacy aircraft and airport fuel infrastructure, which is why we are actively participating in industry efforts to develop new fuel specifications.”

While synthetic fuels are regarded as a relatively near-term solution, RTX is also looking further to the horizon at the potential hydrogen may bring, should it become more widely available on the flight line. It is an area where Pratt & Whitney has significant experience, in fact dating back to the 1950s with a secret Lockheed Skunk Works effort dubbed Project Suntan. This was intended to develop a hydrogen-powered reconnaissance aircraft, capable of flying at high altitude beyond the range of hostile missiles. Although the plan never left the ground, the experience of designing and building a hydrogen-fueled engine proved instructive for Pratt & Whitney.

“We dusted off the designs for Project Suntan and realized that, even back then, our engineers were not just converting an engine to burn hydrogen, they were actually re-thinking the thermodynamic cycle to make the whole system more efficient,” explains Winter. “It’s the same philosophy we applied to our HySIITE project.”

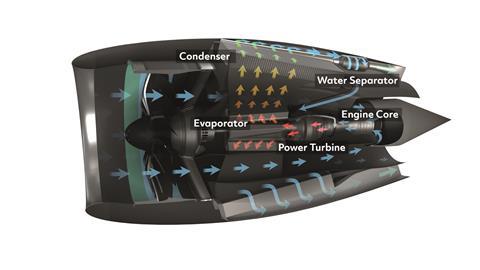

That project — the Hydrogen, Steam-Injected, Inter-cooled Turbine Engine — is a radical concept for a future single-aisle propulsion system, designed to take full advantage of the properties of cryogenic liquid hydrogen fuel. For example, burning hydrogen produces 2.6 times more water than the equivalent amount of jet fuel, potentially a concern for creating contrails.

With HySIITE, that water is captured from the exhaust of the engine, evaporated into steam and re-injected into the combustor, increasing thrust and reducing nitrogen oxide emissions. Meanwhile, a system of intercooling helps create a more efficient system. The project kicked off in 2022, supported by the US Department of Energy and recently concluded with impressive results from rig testing of key sub systems.

“We proved that we could put a condenser in the exhaust and have it survive. We proved we could trap water, one gallon every three seconds. And we’ve shown that we could reduce nitrogen oxide emissions by more than 99%,” says Winter. “Overall, the concept could lead to an engine that is 35% more efficient than a modern GTF engine, which could really help offset some of those other challenges with hydrogen, in terms of aircraft design and fuel production.”

Advancing technologies

On advanced materials, one of Pratt & Whitney’s research programmes is into the composition of future fan blades, using nickel-based super alloys and ceramic matrix composites (CMCs), drawing lessons fro the engineering that goes into Collins’ brakes and the control surfaces on a Raytheon hypersonic missile, both of which operate under ultra-hot conditions. Since 2021, Pratt & Whitney’s dedicated development facility in Carlsbad, California, has been a key centre for advancing CMC technologies.

“Engines really expose the material systems they are made from to the sort of unique conditions that are rarely seen on planet Earth,” says Winter. “Temperatures in engines are hot enough to melt rocks, sometimes exceeding the melting points of surrounding metal structures. When it comes to how we can further improve turbine blade design, we are borrowing technology learnings from across RTX.”

For several decades, RTX has pioneered additive manufacturing, with the technology advancing from a way of swiftly creating components during prototyping to making low-volume production parts for legacy engines, including those for the TF33, which powers the US Air Force’s Boeing B-52s.

But additive manufacturing is not just for older engines. Using an additive manufacturing process called unitization and leveraging expertise across RTX, Pratt & Whitney engineers reduced total part count on the TJ150 engine – designed to power missiles – from over 50 to just a handful, significantly reducing production time and cost. In another example this year, Pratt & Whitney announced an additive-manufacturing-assisted repair for GTF engine components that could reduce the time required for processing a repair by more than 60%.

Further leveraging the potential of AI and machine learning is another priority for Winter and RTX’s global team of scientists and engineers. The technology is used across the company’s design and production chains, from simulating how components will interact before metal is cut, to improving prognostics, where data captured by sensors on an engine can be analysed in real time as soon as the aircraft lands to more efficiently identify maintenance needs.

While development projects take place in several global locations, one of the company’s main innovation hubs continues to be the RTX Technology Research Center next to Pratt & Whitney’s headquarters in East Hartford, Connecticut. It opened in 1929 as part of Frederick Rentschler’s early commitment to the technology of tomorrow, just a few years after Andy Willgoos was drawing early Wasp engine concepts in his suburban garage.

“Rentschler said that every great company needs places where inventive minds can come together, think big, experiment, and design and define the future,” reflects Winter. “If you look across RTX leadership, a lot of people started their careers there. It has helped create this pervasive technical depth in the leadership of the company.”

Pratt & Whitney at 100

To mark the centenary of Pratt & Whitney, FlightGlobal has partnered with RTX to produce a souvenir special looking at the legacy and future of one of the industry’s most powerful and influential brands.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Currently

reading

Currently

reading

Pratt & Whitney at 100: Technology – the future of flight

- 12

- 13