Pratt & Whitney Canada can lay claim to being the industry’s most prolific engine manufacturer, at least in terms of number of variants it has introduced to the segments it serves. Since opening its doors in 1928, the business – based in Longueuil, on the banks of the St Lawrence River opposite Montreal – has designed and certified more than 200 engine models, of which more than 110,000 have been produced.

Powering a multitude of aircraft types, from regional airlines and helicopters to water bombers and large business jets, Pratt & Whitney Canada’s turboprop, turboshaft and turbofan engines as well as its auxiliary power units (APUs) have accumulated more than 1.1 billion hours of service. With nearly 70,000 engines in operation and more than 16,000 customers globally, a Pratt & Whitney Canada-powered aircraft takes off or lands every second, something president Maria Della Posta describes as “a testament to our impact on aviation and the world”.

Pratt & Whitney Canada was originally created as a site for servicing, then assembling Wasp engines, to help ensure access to a growing aviation segment outside the USA. This proved fortuitous as not only did the continued production of Wasp engines and spare parts after the Second World War allow Pratt & Whitney Canada to maintain a steady source of cash flow, it also enabled the business to gain valuable experience catering for a growing pool of general aviation operators.

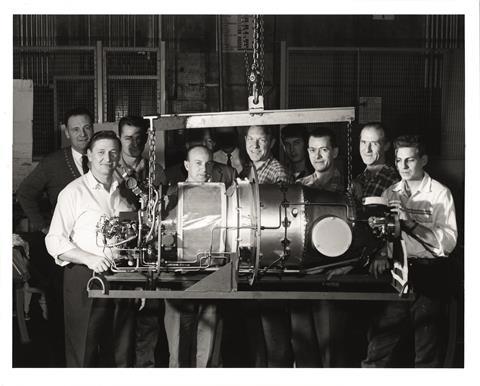

By the late 1950s, Pratt & Whitney Canada saw an opportunity as several small-aircraft companies were in the market for a 500-shaft horsepower (shp) turboprop engine. Engineers in Longueuil got to work developing an innovative reverse flow turbine engine, and after some hitches along the way, the product launched as the PT6 engine was chosen to power a new turboprop version of the piston-powered Beech Queen Air called the King Air.

The King Air entered service in 1964 and the PT6 engine was on its way to becoming a legend. Since then, the turboprop engine, in its many variants, has gone on to power a wide array of top-selling platforms, including the Pilatus PC-12, De Havilland Twin Otter, Daher’s TBM series, the Cessna Caravan, Embraer Super Tucano and many more.

Over the years, Pratt & Whitney Canada’s engineers have continued to enhance the PT6 engine’s performance, increasing power by 40% and fuel efficiency by around 20% compared to the first model, notes Della Posta, “while keeping within the same engine diameter”. In 2019, the newest generation of the PT6, the E-Series, was introduced, powering the PC-12 NGX at launch. It is the first general aviation engine with a dual-channel integrated electronic propeller and engine control system. In 2022, a new variant, the PT6E-66XT, was announced as the engine for Daher’s TBM 960, the latest single turboprop type from the French manufacturer.

Ramp up of the E-Series has been rapid. In April 2024, Pratt & Whitney Canada announced that the 500th PT6 E-Series engine had rolled off the production line in Lethbridge, Alberta. The engine model has already flown more than 300,000 hours and 700-plus engines have been delivered to Pilatus and Daher. It benefits from real-time engine monitoring and support from Pratt & Whitney Canada’s continuously growing service centre network, including 50 owned and designated overhaul facilities strategically located worldwide as well as a world-class Customer First Centre that provides round-the-clock, front-line expertise (celebrating its 35th anniversary this year). Pratt & Whitney Canada continuously reinforces a customer-focused culture that prioritises its customers’ success.

The segment-leading PT6 engine – which spans a power range of 500shp to 1,900shp – has been a “cornerstone of our success and continues to create value for customers after six decades,” maintains Della Posta, a Montreal native who became president of Pratt & Whitney Canada in 2019 and has been with the business since 1985.

“Its reliability, performance and versatility have made it the go-to choice for a wide range of applications, from transport and cargo to agriculture and firefighting to search and rescue missions, whether for fixed wing aircraft or helicopters,” she says. “The PT6 engine has undergone continuous improvements, with the latest variants like the E-Series pushing the boundaries of performance and efficiency. As we look to the future, we are focused on further enhancing these engines to meet the evolving needs of our customers.”

While the PT6 engine put Pratt & Whitney Canada on the map, the business’s success today is also built on many families of products. These include the larger PW100 turboprop engine that powers a series of regional aircraft including those from ATR and De Havilland Canada, as well as a range of turbofan engines installed on business jets from the Embraer Phenom 100 and Cessna Citation family range of light jets to the large-cabin Dassault 6X and the Gulfstream G400, G500 and G600.

The PW100 – a family of 1,800shp to 6,500shp engines – was launched to coincide with the emergence of a new segment that followed US airline deregulation at the close of the 1970s, when carriers were able to serve commuter routes with 50-70 seaters, rather than the smaller types typically powered by the PT6 engine.

Manufacturers such as De Havilland, Fokker, Dornier, and ATR, rushed to fill the gap. As did Pratt & Whitney Canada, with the engine making its debut on the De Havilland Dash 8-100 in 1984.

It went on to power five different aircraft over 1984 and 1985, including the ATR 42 and ATR 72 as well as regional and multi-mission types including the Embraer EMB 120 Brasilia, Fokker 50 and the Dorner 328, and today is the powerplant on the in-development Canadair DHC-515 firefighting aircraft from De Havilland.

The latest development in the family, the PW127XT engine series, entered service on all new-production ATRs in 2022 and was chosen for the upcoming Deutsche Aircraft D328eco. It offers 40% more time on wing, a 20% reduction in maintenance costs and a 3% reduction in fuel consumption compared with its predecessor, “and by recently surpassing 300,000 hours of operation, we’re meeting those commitments”, notes Della Posta.

Pratt & Whitney Canada has produced over 9,000 PW100 family engines – in more than 30 models – and today, powers seven out of every 10 regional turboprops in the 30- to 90-passenger category. “We’re extremely proud of the role we’ve had in shaping the modern regional turboprop segment, since we introduced the transformative PW100 engine family more than 40 years ago,” says Della Posta.

“Continued investment in the efficiency and durability of our turboprop engines is crucial for us, as we’re also supporting our customers to develop current or future aircraft platforms,” she continues. “These aircraft play vital roles in various sectors, and by providing reliable, dependable and efficient engines, we ensure their continued operation and effectiveness.”

Business line

Another prestigious part of the Pratt & Whitney Canada portfolio is its business jet engine range, where it powers more than a third of the aircraft in all segments up to the 16,000lb thrust PW800 engine. The breakthrough in business aviation came with the Cessna Citation I in the early 1970s after manufacturers of other first-generation business jets, such as Learjet and Dassault, looked for new engine suppliers. Today, Pratt & Whitney Canada offers an engine model for virtually any application.

Cessna, as with its Wichita peer Beech on the King Air, has proven a steady customer for Pratt & Whitney Canada over the decades, with the PW300 engine series today powering the midsize Latitude and twin PW545D engines set to do the same for the latest model from the Textron Aviation brand, the Ascend.

PW535 engines power the Embraer Phenom 300, the top-selling light jet for the past dozen years. Meanwhile, Pratt & Whitney Canada was a pacesetter in the very light jet boom of this century’s first decade with the PW600 engine family, and the PW617-F model continues to power the Phenom 300’s smaller sibling, the Phenom 100.

At the top of Pratt & Whitney Canada’s business jet range is the PW800 engine, unveiled in 2017. Quickly finding a home on platforms such as the G400, G500 and G600 as well as the Falcon 6X, the engines in the 10,000-20,000lb (44-89kN) thrust class share a common core with the larger GTF engine family for the Airbus A320neo, A220 and Embraer E2 families.

Della Posta describes the award-winning PW800 engine as “a game-changer for the business aviation segment” and says its “advanced design and performance have made it a preferred choice for Gulfstream and Dassault”.

Rotorcraft propulsion is also a vital part of the Pratt & Whitney Canada product mix, according to Della Posta. “Our engines power a wide range of helicopters that are essential for various missions, including medical evacuations, search and rescue, offshore, VIP, corporate transport, and patrol operations,” she says. “Their reliability and performance in these critical applications highlight their importance in our portfolio and our commitment to supporting the diverse needs of our customers.”

The company’s engine families supporting vertical flight comprise the PT6B, PT6C and PT6T engine models ranging from 1,600-2,000shp, which power the Leonardo A119 Koala and AW139, the Airbus H175 and the Bell 412 helicopters. Meanwhile, the PW200 and PW210A/A1 engine series power the Airbus H135, Leonardo AW169 and Bell 429 helicopters.

Pratt & Whitney Canada has been the champion within the wider RTX organisation when it comes to developing new technologies for advancing aircraft efficiency and performance, including for emerging platforms. “We see these trends as significant opportunities to contribute with our expertise and innovation,” says Della Posta, who notes that Pratt & Whitney Canada is already involved in disruptive propulsion projects, including with Collins Aerospace, to explore advanced hybrid-electric, hydrogen and battery technologies.

A key example is the RTX Hybrid-Electric Flight Demonstrator, led by Pratt Whitney Canada from its development facility in Longueuil. The project leverages a powerful Collins Aerospace one megawatt electric motor, combined with a Pratt & Whitney Canada thermal engine, and is targeting a 30% improvement in fuel efficiency, using a De Havilland Canada Dash 8-100 as the test aircraft. In 2024, the project clocked an impressive milestone of testing the propulsion system to full power of about 1,800shp.

“We’re really proud of the progress made on our hybrid-electric demonstrator project as it exemplifies our commitment to innovation and driving collaboration across Canada’s aerospace ecosystem and internationally,” notes Della Posta, adding that the collaboration with Collins through RTX has a been a “force multiplier” and has helped inform the company’s strategy on developing hybrid-electric propulsion technology across multiple other demonstrator programmes. Pratt & Whitney Canada is the top aerospace investor in the country, devoting more than $500 million annually to research and development.

Pratt & Whitney is Canada is also very active in testing its engines with alternative bio-based and synthetic fuel types, as part of a comprehensive plan to ensure its engines will be ready to operate with future specifications for 100% SAF. This includes demonstration flights with 100% SAF spanning helicopters, regional turboprops, and business jets, in collaboration with the likes of Leonardo, ATR and Gulfstream; the latter recording the world’s first transatlantic flight in a business jet fueled with 100% SAF, in this case, a G600 powered by PW800 engines.

Strong values

As the daughter of an immigrant family growing up in Montreal, Della Posta likens her own life trajectory to that of the business she runs. “I grew up with traditional values, strong work ethics, and a sense of belonging within the family and community,” she explains. “Strong mentors planted seeds of interest in me, and I was encouraged to pursue education and push my limits.”

Della Posta shares that getting to university opened her eyes to a bigger world, much like Pratt & Whitney Canada rising to become a leader in almost all the segments it serves. “Our engines have evolved from the early days to the advanced technologies we deploy today, continually pushing the boundaries of innovation,” she says.

Della Posta’s 40 years with the business began in an era when there were still engineers at Longueuil who had been involved in the launch of the original PT6 – “I had the benefit of learning from them” – and Pratt & Whitney Canada only had two product lines, with the PW100 engine just entering service. “Today it’s close to 15,” she says.

![]()

This growth is also reflected in the proliferation of sites and increasing employee populations, most notably in Poland, where more than 6,000 Pratt & Whitney Canada employees continue to transform production processes and support key programmes across the business. The company’s international and pan-Canadian footprint fosters skilled jobs and sustains a vibrant supply chain.

Pratt & Whitney Canada has done more than simply launch new products over the decades. In many instances, it has effectively created or helped to build segments that previously did not exist. “The reason general aviation is where it is today is a result of the PT6, particularly in single engines,” says Della Posta. The same could be argued for the regional turboprop airline segment, when it up-sized significantly in the 1980s.

Della Posta concludes with a heartfelt thank you to the loyal employees and customers of Pratt & Whitney Canada, acknowledging that the “core” of Pratt & Whitney Canada’s philosophy is an obsession with serving its customer base, 85% of which are operators of one or two aircraft. Combined with a constant drive to innovate and develop new segments, as well as develop talent that stays with the company for decades, “that all culminates in a high level of agility and a consistent growth mindset”, she explains. “One thing you can never do is shrink to greatness. We will always keep our underdog mentality, and diversification will always remain our friend.”

Pratt & Whitney at 100

To mark the centenary of Pratt & Whitney, FlightGlobal has partnered with RTX to produce a souvenir special looking at the legacy and future of one of the industry’s most powerful and influential brands.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

Currently

reading

Currently

reading

Pratt & Whitney at 100: Pratt & Whitney Canada – a propulsion powerhouse

- 9

- 10

- 11

- 12

- 13