Bringing the GTF Advantage into production and offering existing customers its durability benefits through upgrades may be a priority for Pratt & Whitney in the coming years. However, engineers in the business are very much looking to the further future as Airbus and Boeing mull over their strategies to replace their current single-aisle families.

Pratt & Whitney’s geared turbofan technology will be key to delivering manufacturers with the step change in fuel efficiency necessary to justify investment in the next generation of narrowbodies likely to emerge in the 2030s, according to Geoff Hunt, senior vice president at Pratt & Whitney, responsible for driving strategic leadership for current and future programme development.

“We believe there is plenty of runway on the GTF architecture to deliver a second-generation engine with significant improvements to performance and durability” he says. Hunt’s confidence is based on the likely timescale of new aircraft launches from the big two, and the fact that by then the GTF – which is already approaching its tenth anniversary in service – will be a seasoned veteran of the industry.

“The single-aisle market is a high-volume, critical market for the airlines and the airframers, so we have to bring them a mature product. The engine has already flown 40 million hours, and by the time the next-generation single-aisle product comes along, we will have something like a quarter of a billion hours of flying time on that architecture,” he says. “This experience underpins our thinking on how best to extend the fuel efficiency as well as durability to the next generation.”

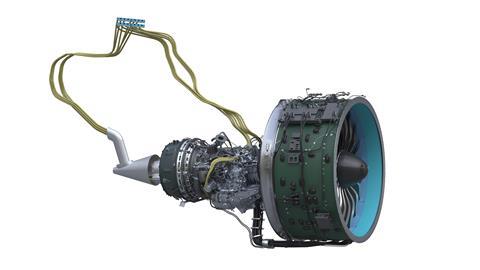

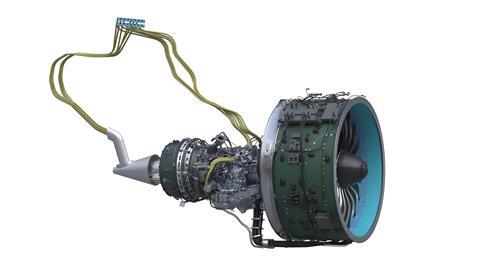

Pratt & Whitney experts are concentrating their efforts in several areas. One is around the propulsive system itself, where the challenge is to increase bypass ratio – the proportion of air that bypasses the core compared to the amount that goes through it. It is an impressive 12.5:1 on the current engine but “we’re pushing for 15 to one”, says Hunt. “It’s all about driving up bypass ratio.”

A second focus for Pratt & Whitney is thermal efficiency and optimising the division in labour between the low-pressure and high-pressure systems within the engine by using advanced materials and aerodynamics. “Our experience in operating a geared architecture really gives us insight into how to enhance these work splits,” says Hunt.

Thirdly, there are benefits from being able to optimise the design of the engine with the nacelle. Pratt & Whitney’s sister RTX business Collins Aerospace is a leader in the structures that house engines on the aircraft. “Having a nacelle company allows us to work on ways to better integrate the engine into the aerostructure to the benefit of our customers,” he explains.

The sibling link also plays into work on new materials and the evolution of electric technologies. “Materials are so critical, and Collins engineers have skills in carbon technologies based on their experience in braking. We will partner very closely to see how we can utilize adjacent materials development,” says Hunt, who adds that Collins also has “a real understanding into how to apply more electric technologies thanks to their experience on the [Boeing] 787 and other aircraft.”

Those synergies within RTX will also come into their own if the airframers make a bold step and opt for hybrid-electric propulsion systems or replace their existing narrowbodies with radical new designs such as a blended wing body. The “shared DNA” with Collins as well as RTX unit Raytheon, with its decades of know-how in missile design and military systems, “enables us to think at an integrated airplane level,” suggests Hunt.

While recent years have seen a revival in interest in developing open fan technology, Hunt has doubts about its viability. “We have tremendous experience with open fans going back to the 1980s and we understand how propeller systems work – we make the biggest ones. Yes, open fans can provide some efficiency over a ducted design, but how much and at what cost?” he says.

“For the future single-aisle applications, we have opted for balancing innovation and maturity, and concluded that a ducted configuration is best. With an open fan, you need to make changes to the airplane that add weight, and shielding becomes an issue,” he adds. “There is a lot of technical complexity that comes with the management of an open rotor which must be matured to assure the reliability that the single-aisle market demands. Noise is also clearly going to be a challenge. The GTF is an incredibly quiet engine and the next generation will be a further evolution on what we have today.”

Finally, while Pratt & Whitney’s focus is on the commercial narrowbody market, is it ready to address a larger segment with the GTF if the market moves that way? “The growth trend towards single-aisle aircraft is pretty clear and I don’t see that changing,” says Hunt. “However, if we felt it was the right thing to do, the technology is scalable.”

Pratt & Whitney at 100

To mark the centenary of Pratt & Whitney, FlightGlobal has partnered with RTX to produce a souvenir special looking at the legacy and future of one of the industry’s most powerful and influential brands.

- 1

- 2

- 3

- 4

- 5

Currently

reading

Currently

reading

Pratt & Whitney at 100: GTF – after Advantage

- 7

- 8

- 9

- 10

- 11

- 12

- 13