In this Q&A with two of GE Aerospace’s Sustainable Aviation Fuel (SAF) experts, learn more about how the engine maker is helping advance the adoption of the alternative fuel in the industry, as well as the importance of 100% SAF testing and increasing SAF production.

In 2022, the number of air travelers worldwide rebounded by 47% over the previous year, and in 2023 the U.N. projects that it will return to pre-pandemic levels, if not higher. As the industry strives to reduce its carbon footprint, the U.S. government has stepped in to help accelerate the process by encouraging the continued development of one piece of the puzzle: sustainable aviation fuel (SAF). In September 2021, the departments of Energy, Agriculture, and Transportation announced the SAF Grand Challenge to reduce the cost of SAF, enhance its sustainability, and expand its production, and last fall those agencies revealed the SAF Grand Challenge Roadmap to scale up SAF production and new technologies. The Challenge set a target of 3 billion gallons of SAF to be produced in the U.S. by 2030 and 35 billion gallons by 2050, which could cover the projected U.S. jet fuel demand. Gurhan Andac, engineering technical leader for aviation fuels and additives at GE Aerospace, says that while we’re far from that target now, there are already concrete agreements in place that project out to almost 1.5 billion gallons by 2030, and there will be more agreements in place soon.

GE Aerospace holds an important place in these efforts, through its work on technology readiness involving GE engines, involvement in SAF qualification, R&D on the feedstocks and technology pathways for producing SAF, and outreach to airlines, among others. To learn more about them and take the pulse of the state of SAF today, we visited with Andac and Joanne Morello, sustainable aviation fuels analyst at GE Aerospace’s Advanced Research Center.

Q: Gurhan, what has GE Aerospace been working on in recent years?

Gurhan Andac: So much is happening in the SAF space with our involvement here at GE Aerospace. We continue to lead first of all in standardization and qualification of SAF; historically, we’ve been involved in that strongly and we continue to do so. I’ve assumed the chair position for the ASTM International committee, which owns and maintains the industry’s only synthetic aviation turbine fuel specification, and oversees the qualifications of SAF pathways. I also chair the ASTM Task Force, standardizing unblended 100% SAF.

We also joined the Roundtable on Sustainable Biomaterials (RSB), a global organization that drives the just and sustainable transition to a bio-based and circular economy. We are a member of SABA, the Sustainable Aviation Buyers Alliance, to help accelerate the path to net-zero aviation by driving investment and adoption of SAF through market-based measures like book and claim. We became a part of the European Commission’s Renewable and Low-Carbon Fuels Value Chain Industrial Alliance, and our focus is on boosting production and supply of renewable and low-carbon fuels.

In the meantime, we continue our role in CAAFI, the Commercial Aviation Alternative Fuels Initiative, a U.S. organization that enforces the value of SAF, enhances the qualification approach, aligns deployment, and shares best practices. And our government affairs teams are engaged in policy and regulation framework development.

Q: Joanne, you joined GE after working on biofuels at the U.S. departments of Energy and Defense. What is your role at GE Aerospace?

Joanne Morello: Even though we’re not directly involved in the production of SAF and primarily address it from the end-use side, we are, in our strategy and approach to sustainability, trying to find ways that we as a company can start to address production-related barriers. And the first part of that journey is to understand the space and the technical landscape as best we can and understand where the supplies might come from in the future: How much? When? What are the different types of SAF going to be? Because we talk about a lot of types of SAF, but they’re all quite different and have different carbon footprints, different costs, different challenges, different potential for scale, depending on the region that you’re in.

Q: How do you both feel about the progress you are making?

Andac: I’m excited. Both on the technical front and the policy and regulation front, there have been encouraging developments. The SAF Grand Challenge, for example, which now gives the U.S. a target to aim to; the diverse incentives under the Inflation Reduction Act. Demand will follow regulation, and investment will be unlocked with the policy, due to the reduced uncertainty in the field.

We are at least very close to that cusp point where we will see a rapid acceleration of SAF production. But again, some of these efforts take time to implement. When you try to put a new SAF facility on the ground, if you start today, it will take five to seven years to realize that in the field. So some of these things are occurring right now, but you won’t necessarily see its fruit, if you will, immediately — they will be realized a few years from now. Those things are happening, so I’m personally quite excited.

Morello: A lot of the necessary ingredients seem to be coming together. Government is really rallying behind us. Several federal agencies are coordinating on this, the customers are clearly energized, and there are a lot of producers trying to develop new technology.

So, I think we have a lot more momentum, but a key thing is that it needs to be sustained. These technologies take a long time to scale up and de-risk and get to the point where they can be broadly applicable and can spread throughout the world. So, we just need the current government emphasis on SAF and the enthusiasm for SAF to sustain itself through the next five to 10 years to get to the goal. It’s definitely good where we are now, but let’s hope it continues.

Q: The biggest hurdle for SAF right now is that there is not enough supply. What kind of progress is being made with SAF production?

Morello: If we look beyond the technology we use to produce all the SAF made today, which is called HEFA [hydroprocessed esters and fatty acids], there are two technologies which are in the demonstration phase and are probably the closest to commercialization. One is the alcohol-to-jet pathway that converts ethanol into jet fuel. That’s a way to use some of the available ethanol as well as future supplies of low-carbon ethanol to make jet fuel. Ethanol and other alcohols seem to be really getting a lot of traction here for the near term. And it’s a technology that’s poised to make a big contribution in the next 10 years or so.

Another technology is gasification. Right now in Nevada there is a first-of-its-kind plant to convert trash that would be destined for the landfill into a synthetic fuel. They’re not making SAF from that fuel right now but they have plans to in the future. Technologies like those, which are able to take some of these solid waste feedstocks, be they trash or forestry residues or things like that — there’s a lot of that stuff lying around, and it’s very abundant and affordable. If we can get those technologies off the ground, that could be a big contributor as well. And there are lots of other exciting technologies in the pipeline.

Q: What impact are the Inflation Reduction Act and the SAF Grand Challenge having?

Morello: There are two programs in the IRA that are the most relevant for SAF. One is a SAF Blenders Tax Credit, which transitions in a few years into the Clean Fuel Production Credit, provides a tax credit to producers on a per-gallon basis. This is important because it helps reduce the production cost, and helps the producers, but it also helps level the playing field between SAF and other transportation fuels like renewable diesel. Right now, it’s a better economic play for the refiners to make renewable diesel than SAF; so the IRA is attempting to address that disparity by giving SAF an additional tax credit.

The second program in the IRA is the FAST [Fueling Aviation’s Sustainable Transition] SAF grant program, which at this point has about $300 million available for new SAF infrastructure. It seems to be targeting either near-term technologies that can be commercial by 2030, or blending facilities, some of those infrastructure challenges, so again, very important for the near term.

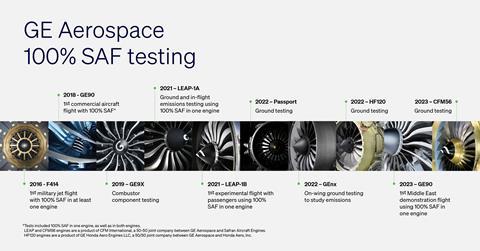

Q: GE Aerospace has been involved with several flight demonstrations in recent years using 100% SAF. What is the importance of testing 100% SAF?

Andac: This is the time to start working on 100% SAF, from a technology readiness perspective as well as from a standardization perspective, because these things take time. Most people don’t realize this, but approved SAF currently being limited to a 50% blend poses a great challenge for the producers, because you don’t necessarily have conventional fuel available to the producer at the SAF production site to prepare the blend. They have to bring in conventional fuel or they have to have a blending facility somewhere, sometimes very far away from the SAF production facility. Going to 100% SAF will eliminate that burden.

Additionally, it will help maximize the carbon benefits that an operator can take advantage of: The more renewable material you use in your operation, the more you will be able to reduce your carbon footprint. Many airlines are interested in 100% SAF from that perspective as well.

These flight demonstrations are also a piece of a larger effort in the qualification process. These test activities allow us to do analysis of engine performance. We collect quite a bit of data in these flights. We compare that performance with historical data for that engine using a conventional fuel — or, in demos where only one engine was fueled by SAF, we compare it with the plane’s other, conventional-fuel-powered engine — and that data is fed into a research report that’s developed under ASTM. This research report serves as a technical substantiation for that fuel to be fit-for-purpose jet fuel, whether a new SAF pathway or 100% SAF. It’s not by itself enough — there are other evaluations that need to take place, fuel composition-wise, component level testing, etc. But from an overall engine performance perspective in a flight condition, it has substantial value.

Q: What do you feel are the most important steps to take this year, whether by GE Aerospace, government, the airline industry, or consumers?

Andac: Our support of our customers is very important. We have regular conversations with our airline customers. We educate them, give them comfort and confidence and guidance in adopting SAF.

We also have put together a technology plan at GE Aerospace to assess our current capability and if need be, develop capability to accommodate higher-blend-ratio SAF and nontraditional SAF options for the airlines and operators to be able to utilize in the future by using our products. That’s something exciting and a new focus for us.

Morello: I think the government needs to continue the programs that it has now and the policies and regulations it has now, but also rally to get these next-generation feedstocks and technologies off the ground, because I think ultimately that will be a huge part of SAF’s future. And it’s not a commercial reality today.

And we have to just to continue the momentum. I think the customers and the airlines need to continue to send very strong demand signals. We also need to start educating the flying public about SAF to help make aviation more sustainable and let them know we’re working on it and we have a path to get there.

This story originally appeared on GE Reports.