Reaching the ambitious targets of the Paris Agreement calls for revolutionary propulsion concepts. With the water-enhanced turbofan, MTU is working on a gas-turbine-based propulsion concept that approaches climate neutrality.

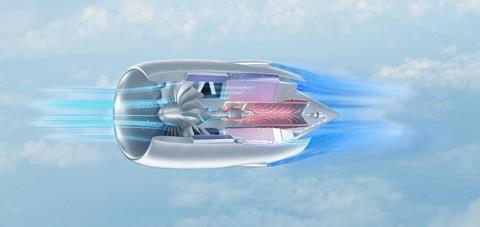

The water-enhanced turbofan, or WET engine, is a propulsion concept that takes full advantage of MTU’s know-how. Utilizing residual heat from its exhaust gas, the WET engine uses a steam generator to vaporize water, which is then injected into the combustor. The water for this is extracted from the exhaust gas by means of a condenser and then separated.

What are the advantages of the WET engine?

The carbon footprint of the WET Engine is unique: it reduces CO2 and NOx emissions primarily by recovering exhaust heat and injecting steam into the combustor. It also curbs the formation of contrails by filtering out any particulate matter from the exhaust gas stream. Recovering the exhaust heat, and thus improving thermal efficiency, reduces energy consumption. When powered by SAF or hydrogen, by 2035 the WET engine could reduce the climate impact of aircraft by about 80 percent compared to a gas turbine engine from the year 2000—making it virtually climate neutral.

Following the planned market launch in 2035, the plan is to further optimize the water-enhanced turbofan by 2050. The use of near drop-in fuels (chemically modified SAF) would achieve the maximum reduction in climate impact. And if the WET engine is powered by hydrogen, this would result in further advantages with regard to climate-relevant emissions.

How does the WET engine work?

The engine’s efficiency is increased by recovering the exhaust energy that would otherwise be lost—this also lowers fuel consumption and CO2 emissions. First, a steam generator produces hot steam. The exhaust gas cools down in the process. As it cools further in the condenser, the water it contains begins to condense. The condensation heat is fed to the bypass flow and the liquid water is separated from the exhaust gas in a water separator. Condensation nuclei are also washed out of the exhaust gas in the process, which reduces the formation of contrails. The water is then brought to a high pressure level by means of a pump and delivered to the steam generator. The steam expands in a steam turbine before being channeled into the combustor. The power is fed into the low-pressure shaft. Injecting the hot steam into the combustor not only increases the engine’s efficiency, but also reduces nitrogen oxide (NOx) emissions.

Where can the WET engine be used?

The WET engine can run on kerosene, sustainable aviation fuels (SAF) or hydrogen, and is suitable for use on short-, medium- and long-haul routes. As a result, it covers the factors that are responsible for virtually the entire climate impact of aviation.