All GE Aerospace engines can operate on approved Sustainable Aviation Fuel (SAF) blends today. GE Aerospace also supports industry initiatives to qualify and adopt 100% SAF through its own testing and through industry collaborations.

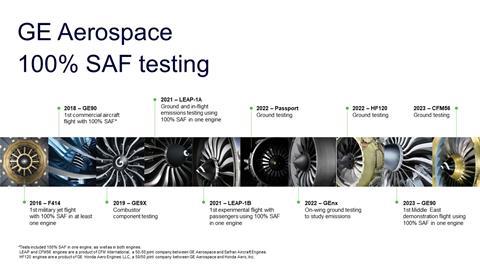

GE Aerospace’s long history of Sustainable Aviation Fuel (SAF) testing in collaboration with industry partners includes the first commercial demonstration flight of biofuel in 2008, the first commercial aircraft flight with 100% SAF in 2018, SAF engine emissions testing, and the first passenger experimental flight in 2021 with 100% SAF in one of the two engines.

SAF reduces lifecycle CO2 emissions

SAF has the same chemical composition as the jet fuel most commonly used today. The key difference is instead of being made from fossil-based sources, SAF is made from partially or completely renewable sources. The use of renewable feedstocks and processes reduces net CO2 emissions over the entire lifecycle.

What’s 100% SAF?

SAF is currently approved for use in blends up to 50% with conventional jet fuel. Efforts are underway to standardize 100% drop-in SAF, which doesn’t require blending and is compatible with existing aircraft and infrastructure.

Advancing industry decarbonization efforts

Ground and flight tests help improve available data to support the standardization and approval of drop-in 100% SAF. Learn more about the efforts to standardize 100% SAF in this FlightGlobal article.